We take pride in being a preferred supplier to the energy sector, both on- and offshore, where the surrounding environment and working conditions are more extreme and challenging than anywhere else.

Coupled with the demand for smooth round-the-clock operations and no room for costly interruptions, our compressors and high-pressure pumping systems must offer total operational reliability and at the same time require a minimum of maintenance down-time.

HIPAQ supplies pressure systems for all of the typical energy applications, such as

Well testing • Well drilling • Mud transport • Pigging • Instrument air • Pipe and pipeline cleaning • Underwater cutting • Chemical injection and cleaning • Sand blasting • Water blasting • General cleaning

Wind farm cleaning and filtration tasks • Substation cleaning • Topside module cleaning

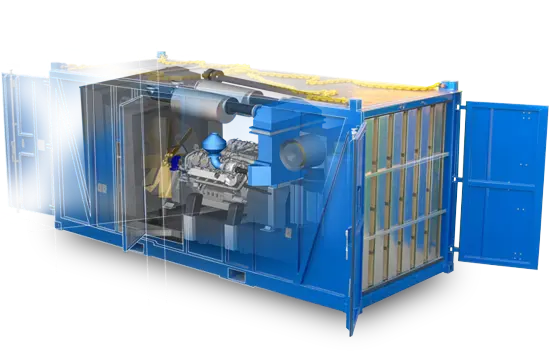

All HIPAQ products are customized for the task at hand, and for the physical space they will operate in. Typical ranges are air compressor systems up to 75 m3/min and 50 bar, and high-pressure systems up to 3000 bar.

HIPAQ delivers for all applications and all climates, whether arctic or tropical. Emphasis is put on compact design with small footprint, and low noise level, along with optimization of service procedures and intervals.

We have extensive knowledge in building for hazardous areas, according to IECEx/ATEX and the majority of machines can therefore be delivered for Zone 1 or Zone 2. HIPAQ has its own patented 3G Safe gas detection system.

Containers, skids and entire units can be delivered in accordance with DNV standards DNVGL-ST- E271, E272 and E273.

HIPAQ is experienced in building according to other standards as well, such as wind sector standards and NORSOK, which means our customers can trust us with even the most complex design, documentation and certification tasks.

We deliver full documentation packages to the highest standards, ensuring a problem-free approval and integration of any unit into its new location.

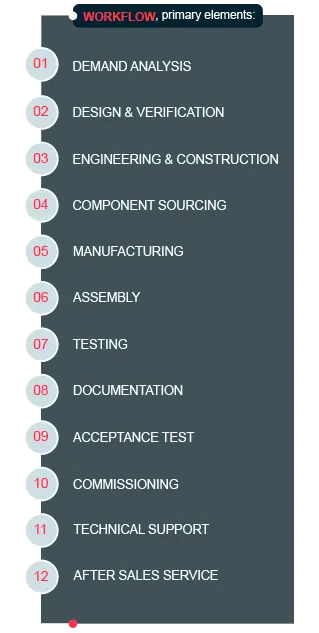

How we work

Complete transparency in every aspect of the manufacturing process

At HIPAQ we are concerned about our customer’s specific requirements and demands. Therefore, we always split the tasks into divisions and part deliveries to ensure the end product meets customer expectations at all times. Throughout the manufacturing process we focus on customer dialogue and involvement to create the perfect solution..

Handcrafted

with care

At HIPAQ we take great pride in constructing strong, sturdy and durable machines. The right combination of quality components and excellent craftsmanship makes this possible.

3D CAD-design and construction

We use 3D CAD design as core tool for the design of our solutions. This yields many benefits, such as traceability, and maximizes the likelihood of detecting potential problems early in the production process.

The 3D drawings also serve as documentation prior to the assembly process and clarify the final system layout to us and our customers.

Respecting the

environment

– and the people

in it!

At HIPAQ we work continuously with our HSEQ: Our policy is to meet applicable standards governing quality control, environmental protection and occupational health and safety at all times. We analyze our work routines and provide relevant training. Our quality control system involves every part of our organization – from initial query to final delivery.

Our management system is certified according to:

- ISO 9001:2015

- ISO 14001:2015

- ISO 45001:2018

Our products can be supplied according to all class majors.

Hipaq has qualified for the

Achilles Joint Qualification

System for the oil- and gas industry.

Hipaq is a member of the

Danish Export Association

and the Danish Marine and

Offshore Group (DMOG).