Engineered to boost

At HIPAQ we design various pressurized systems for manufacturing companies and public institutions. The solutions are often made for concrete renovation, high pressure cleaning of heat exchangers, general maintenance, surface cleaning and removing rust and basecoats.

Combined heat and power plants use our high pressure solutions for major cleaning tasks and integrate the systems into the production plant. A large number of medium-sized and large companies specializing in cleaning choose solutions from HIPAQ.

These solutions are usually precisely adapted to customer-specific wishes and requirements. This also applies to servicing during the running-in period.

- Water blasting systems

- Cleaning systems

- Accessories for all pressure levels in stock

- Electrical, diesel driven, hydraulic driven systems

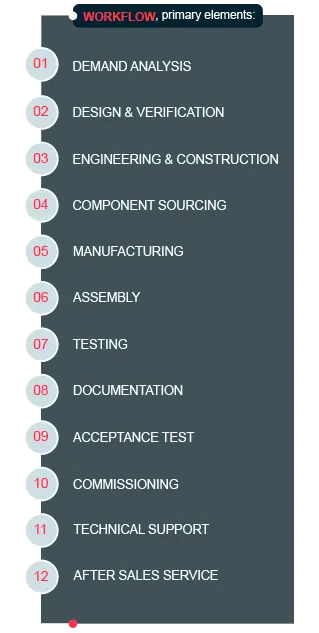

How we

work

Complete transparency in every aspect of the manufacturing process

At HIPAQ we are concerned about our customer’s specific requirements and demands. Therefore, we always split the tasks into divisions and part deliveries to ensure the end product meets customer expectations at all times. Throughout the manufacturing process we focus on customer dialogue and involvement to create the perfect solution.

Handcrafted with

care

At HIPAQ we take great pride in constructing strong, sturdy and durable machines. The right combination of quality components and excellent craftsmanship makes this possible.

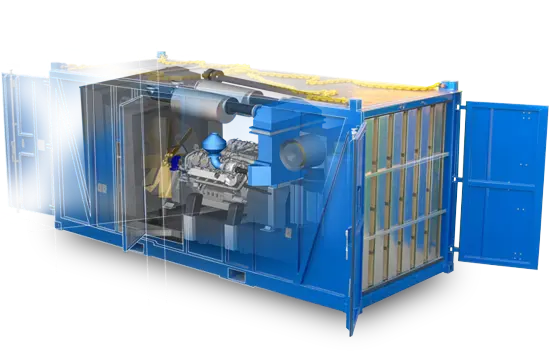

3D CAD design and construction

We use 3D CAD design as core tool for the design of our solutions. This yields many benefits, such as traceability, and maximizes the likelihood of detecting potential problems early in the production process.

The 3D drawings also serve as documentation prior to the assembly process and clarify the final system layout to us and our customers.

Respecting the

environment

– and the people

in it!

At HIPAQ we work continuously with our HSEQ: Our policy is to meet applicable standards governing quality control, environmental protection and occupational health and safety at all times. We analyze our work routines and provide relevant training. Our quality control system involves every part of our organization – from initial query to final delivery.

Our management system is certified according to:

- ISO 9001:2015

- ISO 14001:2015

- ISO 45001:2015

Our products can be supplied according to all class majors.

Hipaq has qualified for the

Achilles Joint Qualification

Systemfor the oil- and gas

industry.

Hipaq is a member of the

Danish Export Association

and the Danish Marine and

Offshore Group (DMOG).